From Junk to Joy

I've always been a huge fan of 3D printing. Back in school, I learned how to create technical drawings and take precise measurements—skills that naturally led me into CAD modeling, which quickly became a fun and rewarding hobby. I started out with a basic FDM printer, but these days I primarily use a resin 3D printer—specifically, the Anycubic M5s Pro. It’s perfect for printing highly detailed miniatures, which ties into my painting hobby. That said, it also proves incredibly useful for more practical applications, like printing mechanical or replacement parts for repairs.

When a part requires properties that resin can’t provide—like greater strength, flexibility, or heat resistance—I often turn to professional services like JLCPCB, which offers manufacturing in materials like stainless steel and flexible polymers. While these replacement parts usually cost just a few euros, the satisfaction of repairing something instead of throwing it away is priceless. Plus, every project helps me refine my modeling skills and learn more about materials and design.

Project 1: Razer Orbweaver Chroma Repair

One of my favorite rescues was a Razer Orbweaver Chroma mechanical keypad that I picked up for just €9. It was sold without a cable, and even the seller didn’t know what had happened to it. Interestingly, the Orbweaver doesn’t use a standard detachable USB cable—nor is an official replacement available—making it a tricky device to repair if the original is missing or damaged.

After opening it up and doing some measurements, I discovered that internally, the keypad uses a regular USB 2.0 connection. Rather than ordering a specialty connector or waiting on parts from Amazon, I spliced a USB cable I had on hand and carefully soldered it to the appropriate points on the PCB.

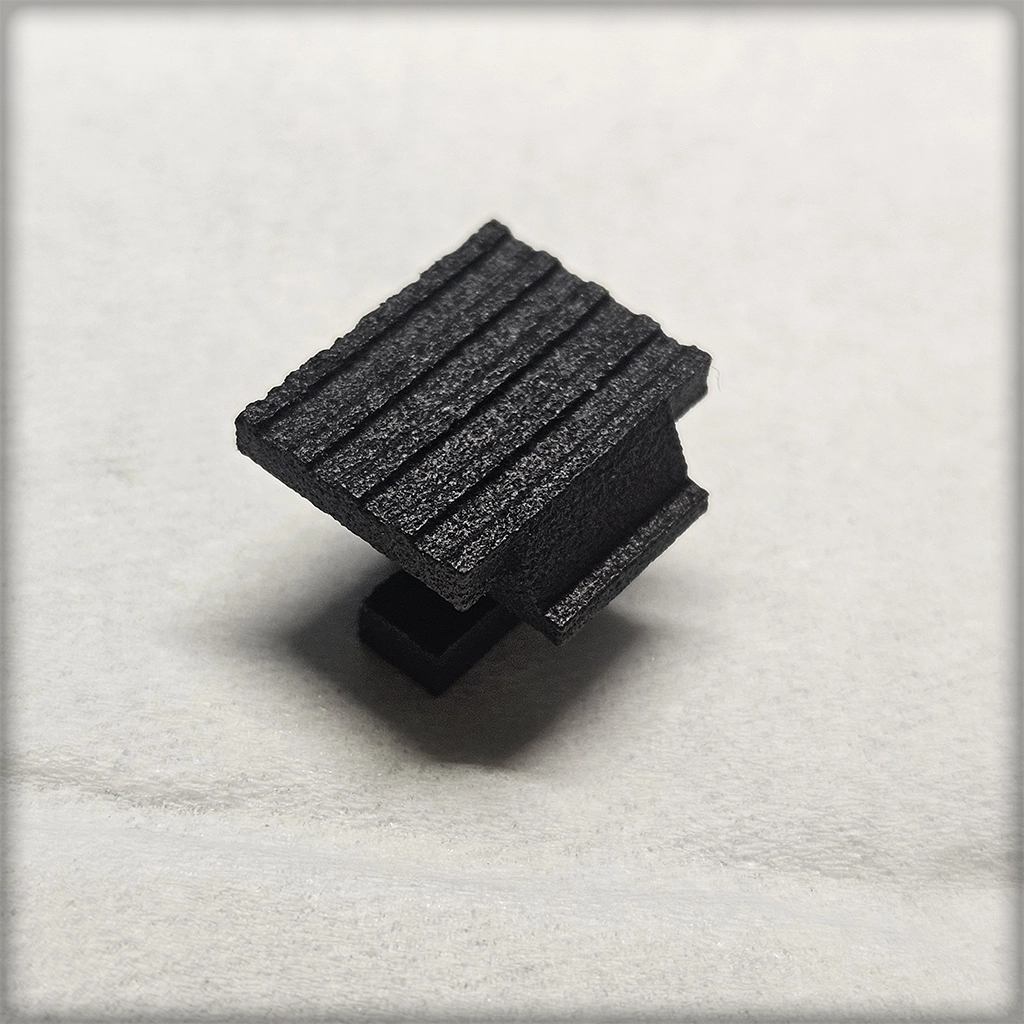

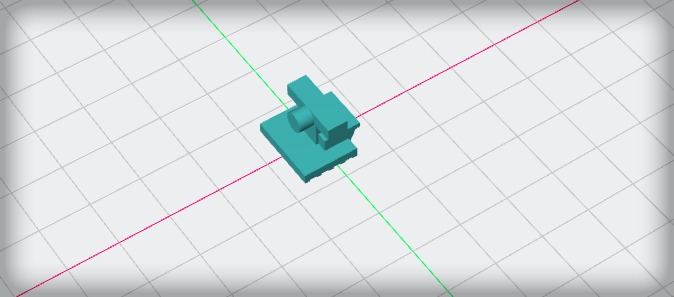

To my surprise, the Orbweaver powered on immediately. All keys and microswitches were fully functional, with no ghosting, double inputs, or other issues common to aging peripherals. To finish the repair, I designed and printed a small cable holder to secure the new cable in place, then glued it in for stability.

With this simple modification, the Orbweaver was fully restored—ready to be used for automating workflows, macros, and commands in software and games. A device that would otherwise have ended up in a landfill is now back in action, performing better than ever.

Project 2: Sandwich Maker Reinforcement

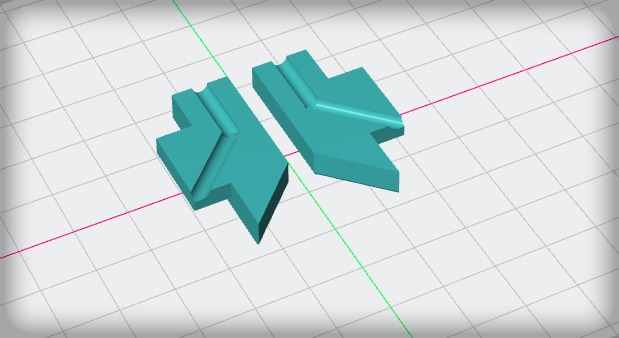

Another repair involved a sandwich maker (this model on Amazon) that I accidentally damaged by preheating it without the baking plates installed. As a result, the plastic latch on the bottom, which holds the plate in place, melted from the heat.

The unit was practically new, with barely any use, and the non-stick plates were still in excellent condition. I first tried printing a replacement latch using rigid resin to see if it could handle the heat. It couldn’t—the part warped quickly under thermal stress. That’s when I turned to JLCPCB and had a stainless steel latch manufactured. At just €8 including shipping, it was an affordable, durable fix that permanently restored functionality to the appliance.

Conclusion

With just a digital caliper, a bit of experience in 3D modeling software, and access to a 3D printer or manufacturing service, you can breathe new life into countless gadgets and tools. Not only does this approach keep more devices out of the landfill, but it also deepens your technical knowledge and problem-solving skills.

Whether it's a high-end gaming accessory or a simple kitchen appliance, there's something incredibly satisfying about fixing what’s broken—and making it even better than before.